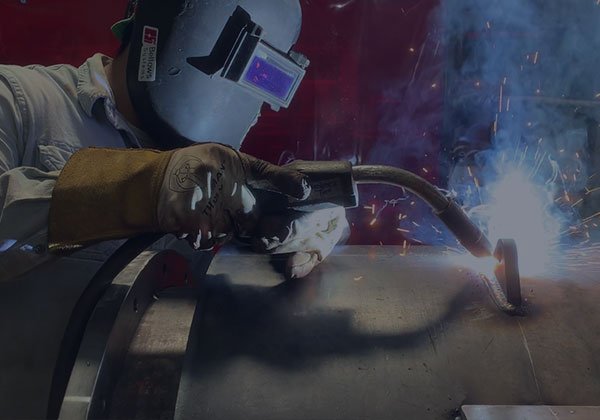

Precision fabrication and certified welding

With an experienced in-house team of fabricators and welding specialists, Bellows Systems offers a broad range of metal fabrication services for our bellows, expansion joints and related components.

Our team is skilled in precision cutting, forming and joining, and is qualified in manual and semi-automatic welding processes including GTAW/TIG, GMAW/MIG and FCAW. With over 200 approved welding procedures across various material combinations, we can support new designs, custom builds and qualification-tested assemblies tailored to your application requirements.

Our Manufacturing Team

Compliance with Manufacturing Standards

Our fabrication and welding activities are carried out in strict accordance with established industry codes and best practices. We follow qualified procedures, use certified personnel and maintain detailed documentation to ensure every weld, component and assembly meets or exceeds applicable manufacturing standards.

This commitment to compliance, traceability and quality control helps our products perform reliably in demanding service conditions.

Manual Welding Procedures

Our welding team is qualified in a range of manual procedures that support precision fabrication, high-integrity joints and consistent quality across diverse alloys and thicknesses. Each procedure is applied using approved weld procedures, qualified personnel and appropriate inspection so that every weld meets the required service, safety and code expectations.

- Gas Tungsten Arc Welding (GTAW / TIG)

- Gas Metal Arc Welding (GMAW / MIG)

- Flux-Cored Arc Welding (FCAW)

- Brazing

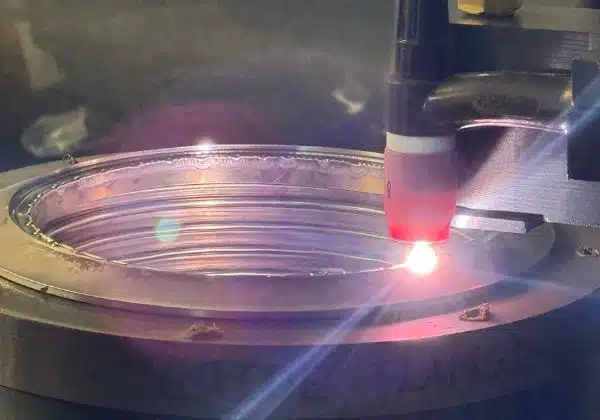

Semi-Automatic Procedures

Our semi-automatic welding capabilities are focused on delivering high repeatability, tight process control and superior weld quality for critical components. Using advanced power sources and automated or mechanized setups, our team applies qualified procedures and rigorous inspection practices to support production welding, special processes and high-specification customer requirements, including PRI NADCAP approved operations.

- Gas Tungsten Arc Welding (GTAW)

- Plasma Arc Welding (PAW)

- Laser Beam Welding (LBW)

- Resistance Seam Welding (RSEW), PRI NADCAP special process approved

Latest News & Blog