Engineered Products to meet your Industry or Project Specific Requirements

For over 40 years, Bellows Systems has been a leader in providing innovative expansion joint solutions for a wide range of industries and applications. We have an extensive line up of standard products to suit your project requirements.

We stock a large variety (size and type) of bellows elements and fittings that can be quickly assembled to meet your needs in a timely manner.

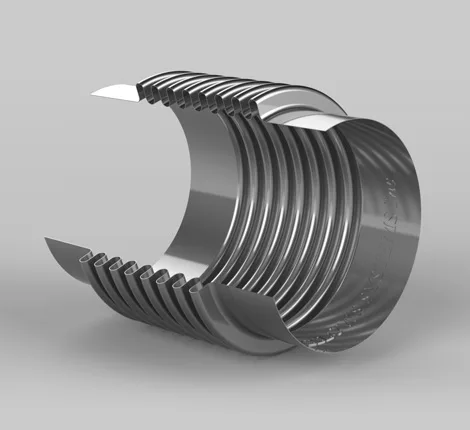

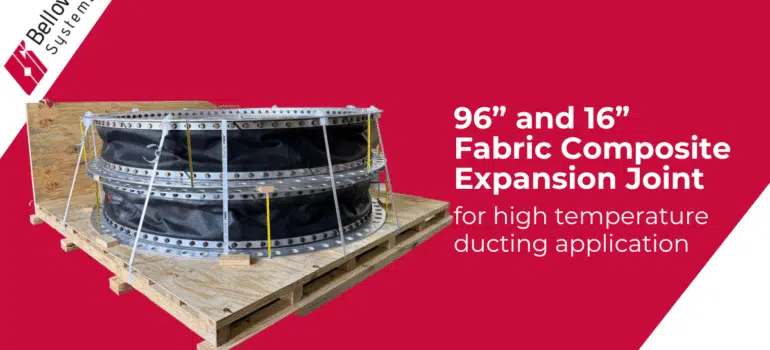

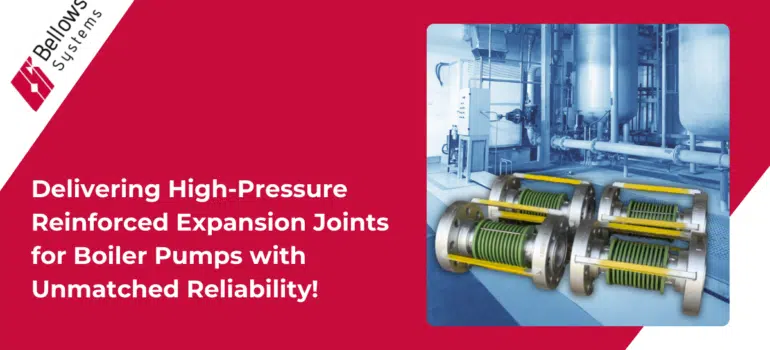

Bellows Systems designs and manufactures wide range of Bellows, Expansion Joints and Exhaust Systems

Looking for Standard Bellows, Custom Expansion Joints or Complete Exhaust Systems, we can deliver.

Why Choose Bellows Systems?

Bellows Systems is a single source for industry’s most complete line of METAL BELLOWS, EXPANSION JOINTS & EXHAUST MANIFOLD SYSTEMS!

We specialize in multi-ply, long life expansion joints and can provide engineering assistance for any of your expansion joint/ metal bellows needs. Bellows Systems also helps multiple clients to build integrated systems and assemblies.

What our customers are saying about us

Chief Engineer

Major Marine & Shipping CompanyExceptional Service from Bellows-System Inc. Producing high quality bellows in record time. Customer service and delivery was excellent. I would highly recommend them for your bellows needs!

Purchasing Manager

Aerospace OEMBellows Systems has been a great company to work with since the transition of new ownership a few years ago. They are willing to work through the issues and provide quality parts.

Lead O&M Tech

Midstream Oil & Gas OperatorBeen buying from bellows for years always a good product. Nikki Hughes is very good about keeping you updated on your order.