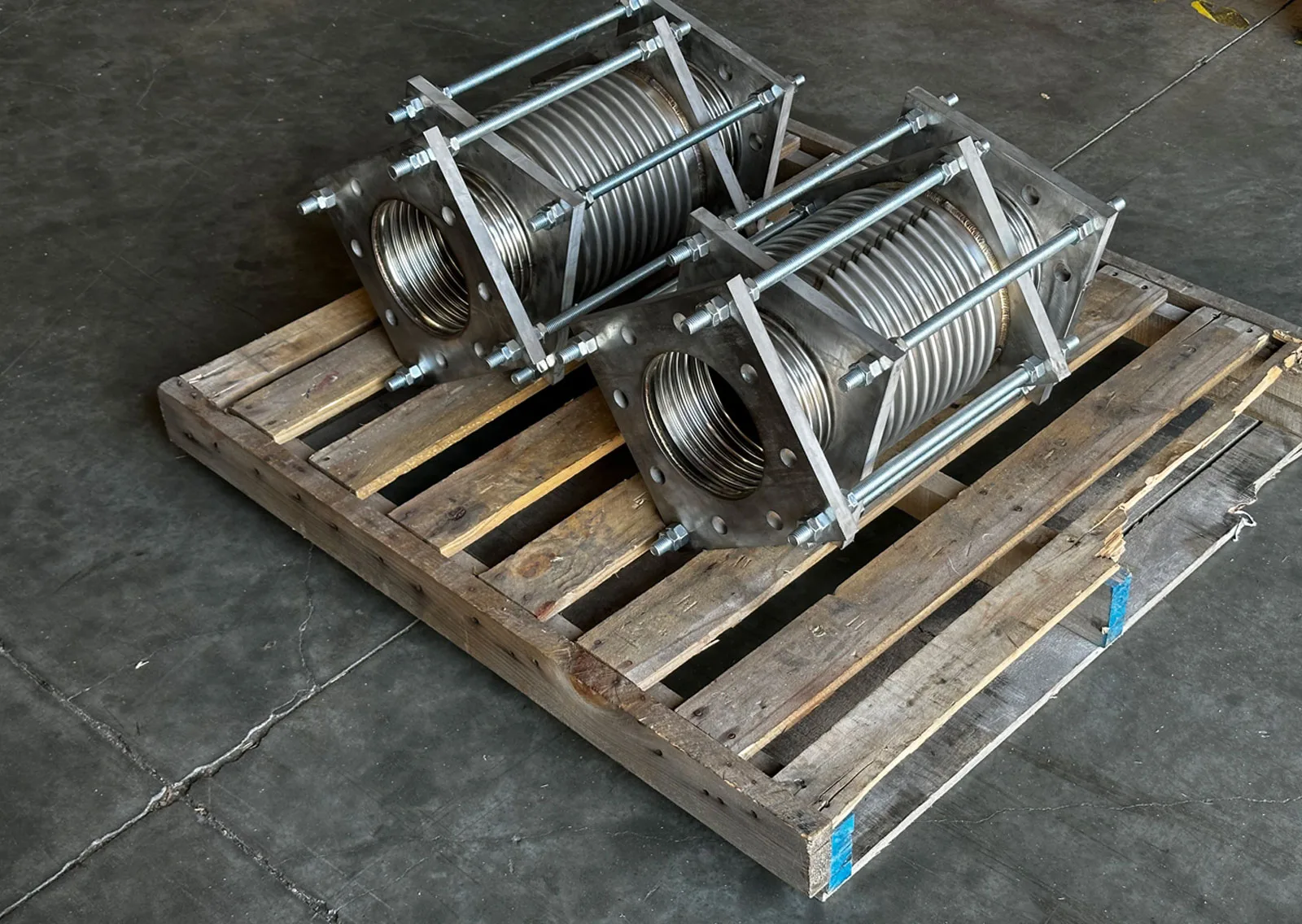

Pressure Balanced Expansion Joint are used to absorb pressure thrust load

A Pressure Balanced Expansion Joint provides another method by which it is possible to eliminate pressure thrust, reduce anchor loads, and make possible the relocation of an anchor at a more accessible and advantageous position. Pressure Balanced Expansion Joints are particularly well suited to applications involving rotating machinery such as turbines and pumps, where it is desirable to reduce pressure thrust and, external loadings on equipment to minimums. The pressure balanced expansion joint can be either inline type or elbow type. The use of an Elbow type Pressure Balanced Expansion Joint necessitates a change in the direction of the piping.

In many applications, some lateral deflection is present on the line side of a Pressure Balanced Expansion Joint. Where the magnitude of the combined axial and lateral movement exceeds that which a single bellows can absorb, it is necessary to equip the line side of a Pressure Balanced Expansion Joint with two bellows. The balancing side requires only enough corrugations to compensate for the axial displacement. To compute the force to deflect this type of Pressure Balanced Expansion Joint, add to the total forces outlined above, the force to deflect the unit laterally.

Alternately, an In-line Pressure Balanced Expansion Joint can be used when axial deflection is present and anchoring is not a suitable option. The operating principle is the same as the elbow type expansion joint, with an intermediate bellows with large thrust area is used to absorb the thrust pressure loads from the In-line bellows.

A Pressure Balanced Expansion Joint (Elbow type) is normally a double bellows Expansion Joint with a side outlet between the bellows. The ends of the bellows are tied together so that as one bellows compresses due to axial movement, the opposing bellows opens an equivalent amount.

The pressure thrust of the line bellows is opposed by that of the balancing bellows and is effectively reduced to zero.

The only forces left are

- force to compress line bellows,

- force to extend balancing bellows,

- friction generated by any alignment guides installed on line side.

The force to deflect a Pressure Balanced Expansion Joint is the sum of forces (1), (2), and (3).

To learn more about our Pressure Balanced Expansion Joint or other products, call us at

(800) 233-0623 or email us at sales@bellows-systems.com.