Testing and Qualification

With an experienced in-house testing and qualification team, Bellows Systems validates the performance and reliability of our bellows, expansion joints and custom assemblies under realistic service conditions.

Our facilities are equipped for a full range of non-destructive examination and mechanical testing, enabling cyclic fatigue, pressure and axial spring rate validation on standard and engineered designs to confirm compliance with application and code requirements.

Our Capabilities

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) is integral to our quality assurance program, allowing us to verify weld integrity, material soundness and dimensional compliance without affecting the service life of the component.

- VT (Visual Testing / Examination)

- PT (Penetrant Testing)

- Visible Dye Penetrant Testing

- Fluorescent Dye Penetrant Testing (FPI / FPT)

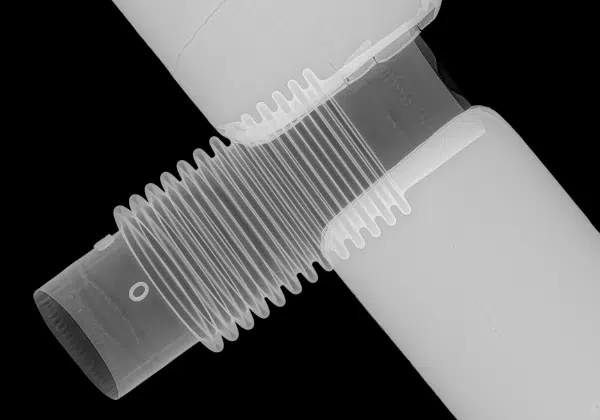

- RT (X-Ray Radiography)

- dRT (Digital Radiography)

Metallographic Testing

Metallographic testing is used to examine the internal structure of materials and welds, providing insight into grain structure, heat-affected zones, fusion quality and potential defects that are not visible on the surface. By preparing and evaluating samples under controlled procedures, we can verify conformance to welding procedure qualifications, material specifications and applicable codes, supporting reliable performance in critical applications.

- Metallographic Sample Preparation (ASTM E3-11)

- Sample Sectioning, Grinding, Polishing

- Sample Etching, Cleaning, Mounting

- Metallographic Evaluation (AWS D17.2)

Mechanical Testing

Mechanical testing is carried out to confirm that our bellows and expansion joints can withstand service loads, movements and pressures while maintaining structural integrity and leak tightness.

- Cyclic Fatigue Testing

- Bellows Spring Rate Validation Test

- Axial Spring Rate

- Lateral Spring Rate

- Angular Spring Rate

- Leak Testing

- Air leak (bubble under water)

- Air leak (soap bubble test)

- Helium Leak Testing

- Pressure Testing

- Pneumatic Pressure Test

- Hydrostatic Pressure Test

Latest News & Blog