Fabric expansion joints play a critical role in managing movement, vibration, and thermal stresses in large-scale duct systems. But when it comes to aerospace research environments, the complexity of application increases significantly. These joints must perform reliably under high temperatures, support system flexibility during propulsion testing, and maintain integrity over multiple thermal cycles.

This article explores how Bellows Systems, Inc. engineered and supplied large-diameter fabric expansion joints for an advanced aerospace research facility in the United States, addressing unique technical challenges that standard components couldn’t meet.

Engineering Requirements in Aerospace Research

Unlike traditional process plants, aerospace research centers operate under extreme test conditions that simulate real-world propulsion scenarios. The duct systems in such facilities are subject to:

- Rapid and repeated thermal cycling

- High-velocity airflow and turbulence

- Vibration and mechanical movement

- Precise dimensional constraints

To handle these variables, expansion joints must be custom-engineered for high temperature performance, movement compensation, and longevity — while still integrating seamlessly into existing system layouts.

Project Scope and Component Details

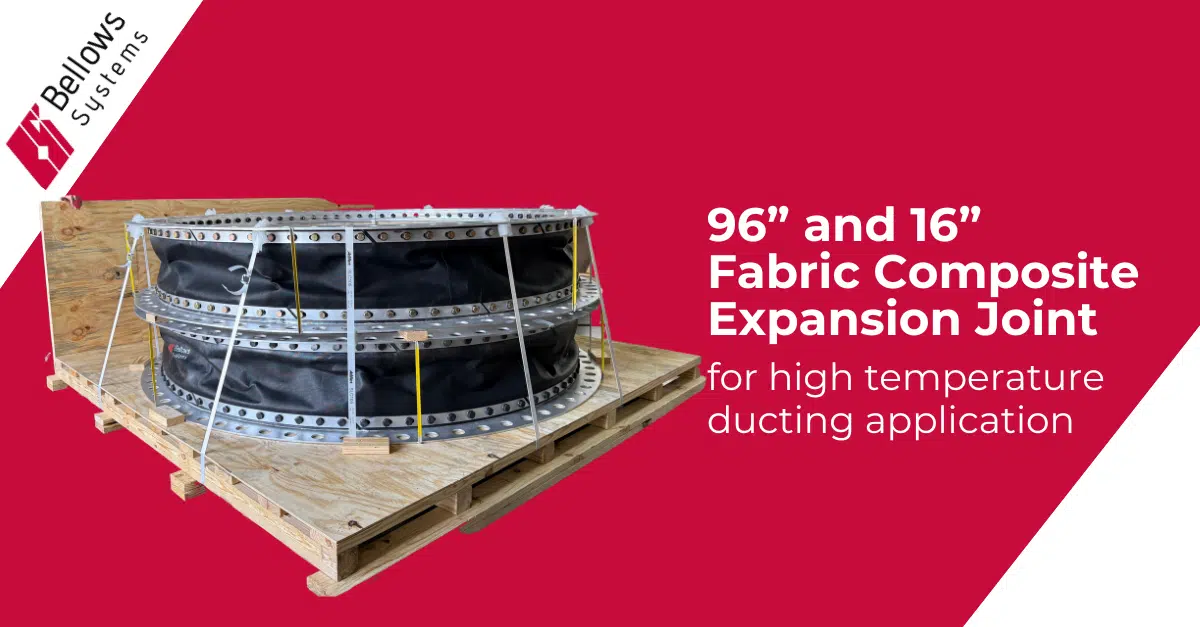

Bellows Systems was tasked with designing fabric expansion joints that could operate under such stringent demands. The components supplied included:

- Two round fabric expansion joints

– 96 inches in diameter

– 18 inches in overall length - One round fabric expansion joint

– 16 inches in diameter

– 24 inches in overall length

Design and Material Considerations

The success of a fabric expansion joint in aerospace environments depends heavily on material selection and movement design.

- High-temperature fabrics were chosen to withstand intense heat generated during test runs.

- The multi-layer structure helped isolate vibrations and reduce thermal transmission.

- The joints were designed to accommodate axial, lateral, and angular movements, ensuring minimal stress on adjoining ducting systems.

In addition to mechanical function, these joints needed to meet tight installation tolerances, making dimensional accuracy and fastening system integrity essential.

Performance and Outcome

Following delivery and installation, the fabric expansion joints were integrated into the research facility’s test system. They performed reliably under multiple test cycles, maintaining structural integrity, eliminating leakage, and absorbing system movements as intended.

By choosing a tailored solution rather than standard catalog joints, the facility was able to ensure:

- Greater protection for test infrastructure

- Reduced maintenance needs

- Extended service life of connected equipment

- Reliable operation in data-sensitive test environments

Final Thoughts

Supplying expansion joints for aerospace research facilities requires a deep understanding of materials, motion, and thermal dynamics. This project reflects how Bellows Systems, Inc. applies engineering expertise to deliver precision-crafted expansion solutions for highly specialized applications.

Whether for high-temperature propulsion testing or vibration-sensitive duct systems, fabric expansion joints must be engineered for the environment and that’s exactly what was achieved here.