Maintain System Integrity: Essential Duct Expansion Joints for Your HVAC

What are duct expansion joints?

Duct expansion joints are flexible connectors installed within HVAC systems to handle various challenges that could disrupt airflow and damage the ductwork. They act as silent guardians, ensuring the system’s efficiency and longevity.

Why Use Duct Expansion Joints?

- Protect Against Thermal Expansion: As temperatures fluctuate, ducts naturally expand and contract. Expansion joints absorb this movement, preventing stress on duct connections and potential leaks.

- Isolate Vibration and Noise: Fans, blowers, and other equipment can introduce unwanted vibrations into the ductwork. Expansion joints act as shock absorbers, minimising noise transfer and protecting duct components from wear.

- Accommodate Misalignment: During installation or due to building movement, duct sections may become slightly misaligned. Expansion joints provide flexibility, ensuring a proper seal and optimal airflow.

- Safeguard Against Seismic Activity: In earthquake-prone areas, strategically placed expansion joints can absorb seismic movement, protecting your ductwork from significant damage.

Types of Duct Expansion Joints:

- Fabric Expansion Joints: These lightweight and cost-effective options are ideal for low-pressure applications. Constructed from flexible high strength composite fabrics like fiberglass textile with PTFE coating, they offer good thermal expansion absorption, resistance to corrosive conditions and good temperature resistance.

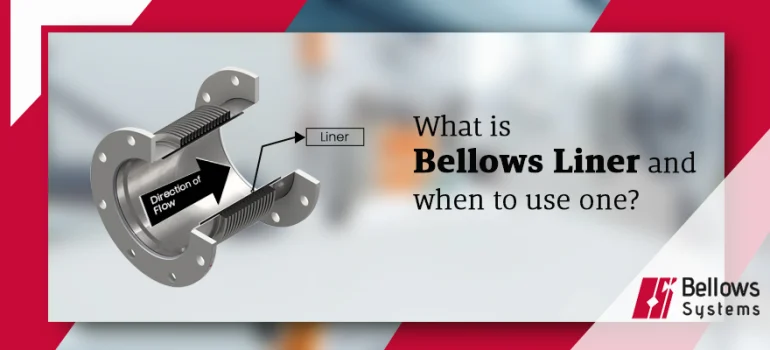

- Metallic Expansion Joints: For high-pressure and high-temperature environments, metallic expansion joints with flexible metal bellows are the perfect choice. They are more durable than fabric joints, offering superior resistance to tears and punctures.

- U-shaped Expansion Joints: A simple and economical solution for low-pressure and low-movement applications. These joints consist of a U-shaped duct section with flexible bends on either side.

- Rectangular Expansion Joints: Specifically made for rectangular or square ducts, they can absorb thermal movements and vibration.

Choosing the Right Duct Expansion Joint:

The optimal expansion joint for your project depends on several factors:

-

- Pressure Rating: Consider the maximum pressure your ductwork will handle.

- Temperature Range: Ensure the joint can withstand the expected temperature fluctuations.

- Movement Requirements: Determine the amount of expansion and contraction the joint needs to accommodate.

- Space Constraints: Select a joint size that fits comfortably within the available space.

Bellows Systems offers a comprehensive selection of high-quality duct expansion joints to meet your specific needs. Our team of experts can assist you in choosing the right joint for your application, ensuring optimal performance and long-lasting system integrity.

Contact us today to discuss your duct expansion joint requirements and experience the difference a seamless HVAC system can make.