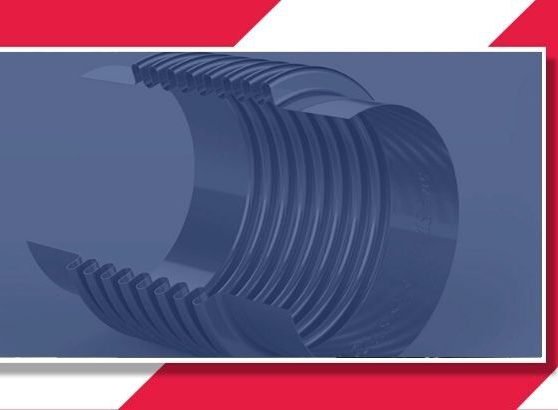

Multi-ply bellows are made up of a multiple telescoping tube (or plys) of sheet metal. The telescoping tubes are formed (Expanded mandrel or hydraulic) together to form each convolution.

Why are they better than single-ply bellows?

- They offer redundance in the event of inner ply failure.

- The offer much lower stiffness.

- Leak detection measures can be incorporated to detect ply failure hence providing time to change out the existing expansion joint.

- Much higher cycle life per corrugation.

- Corrugated length can be much shorter to achieve similar movement and cycle life performance to that of a single ply bellows.

What are the drawbacks?

- They have higher meridional bending stress.

- They have less resilience to corrosion due to the individual wall thickness.

- Higher ply count can result in slightly higher manufacturing cost.

- Increased in-plane and column instability compared to a similar single ply construction.

- Difficult to repair in the field due to the much thinner ply thickness.